Cooperation approach

Our library keeps growing and is under permanent revision, improvement and validation.

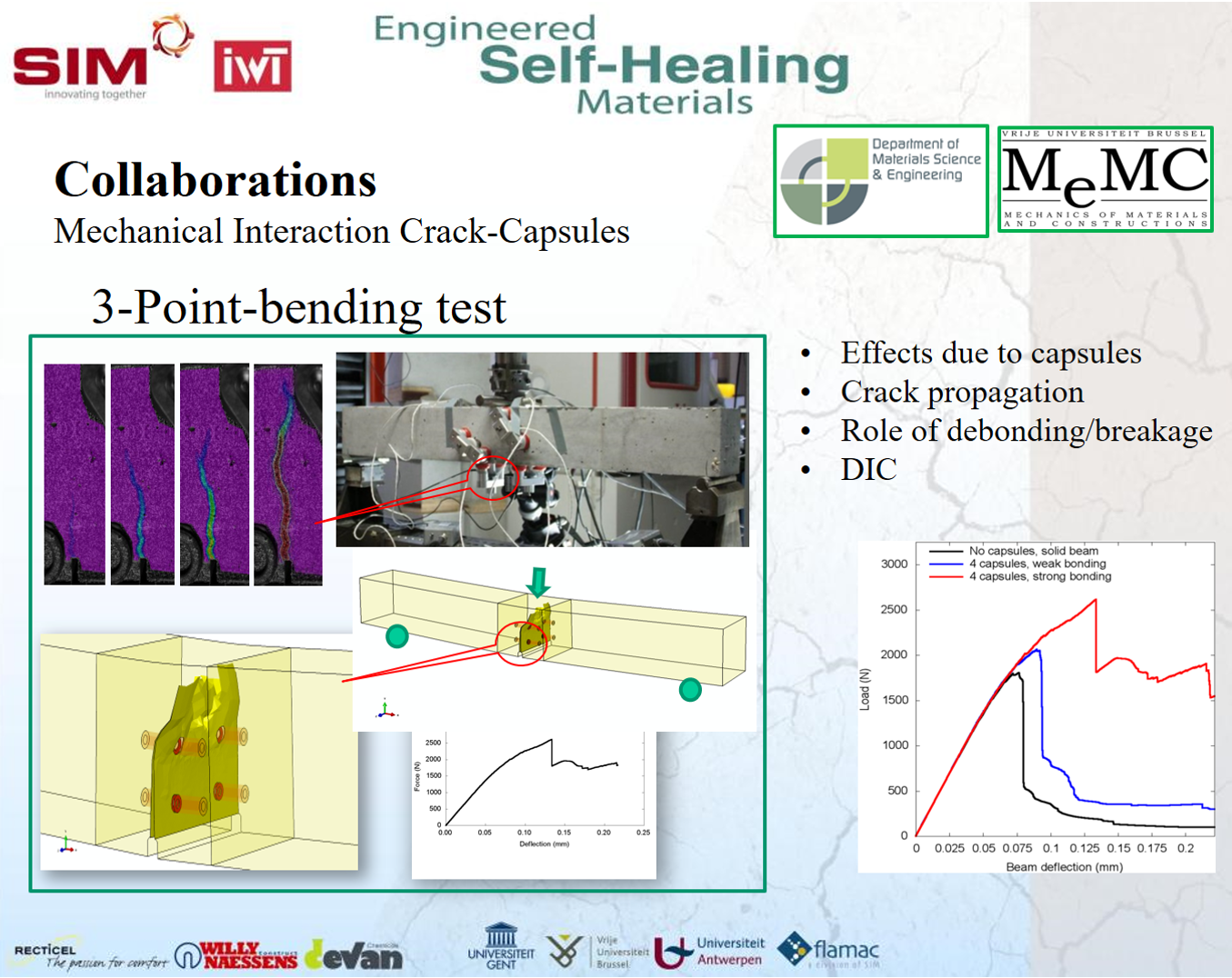

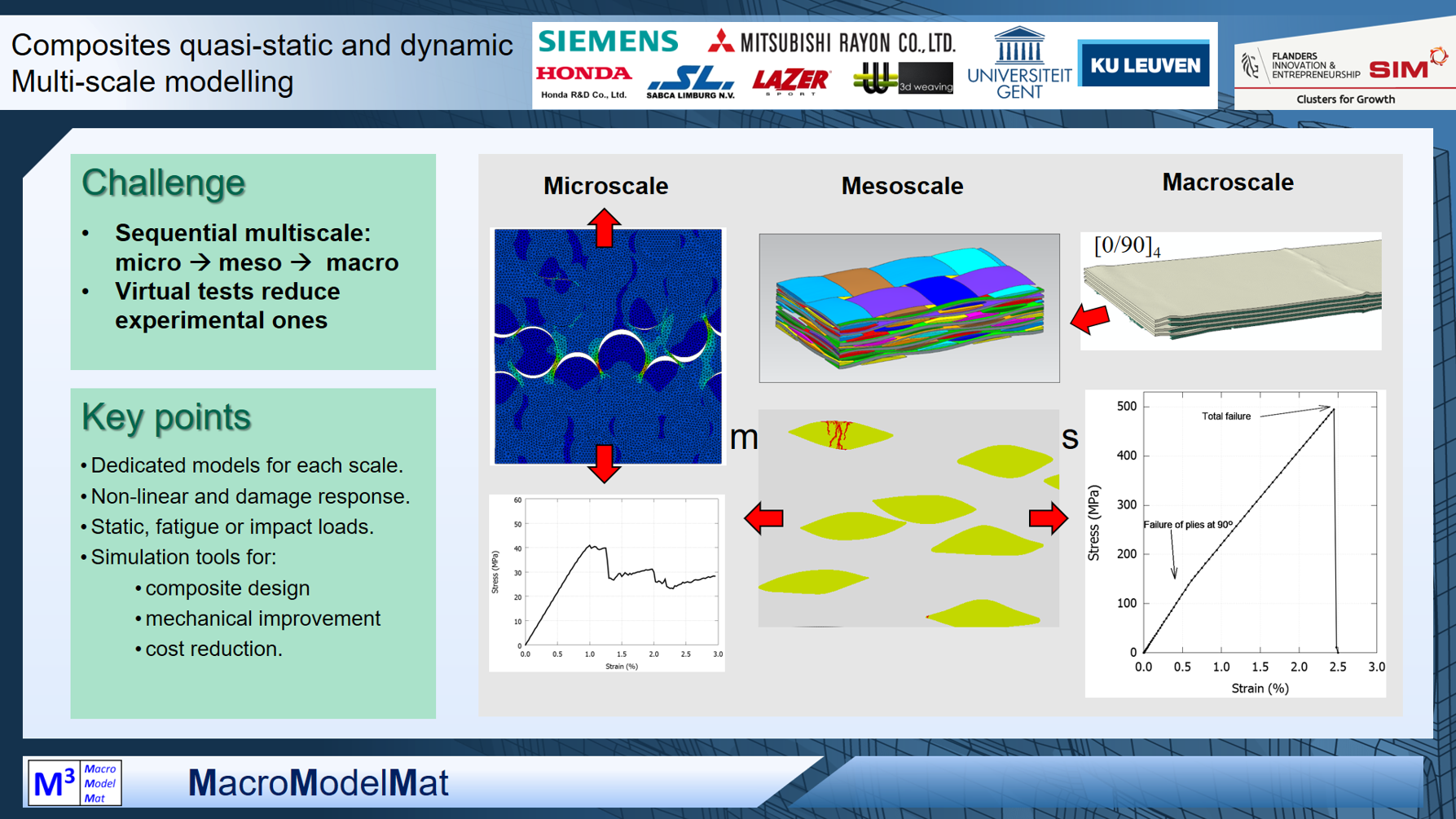

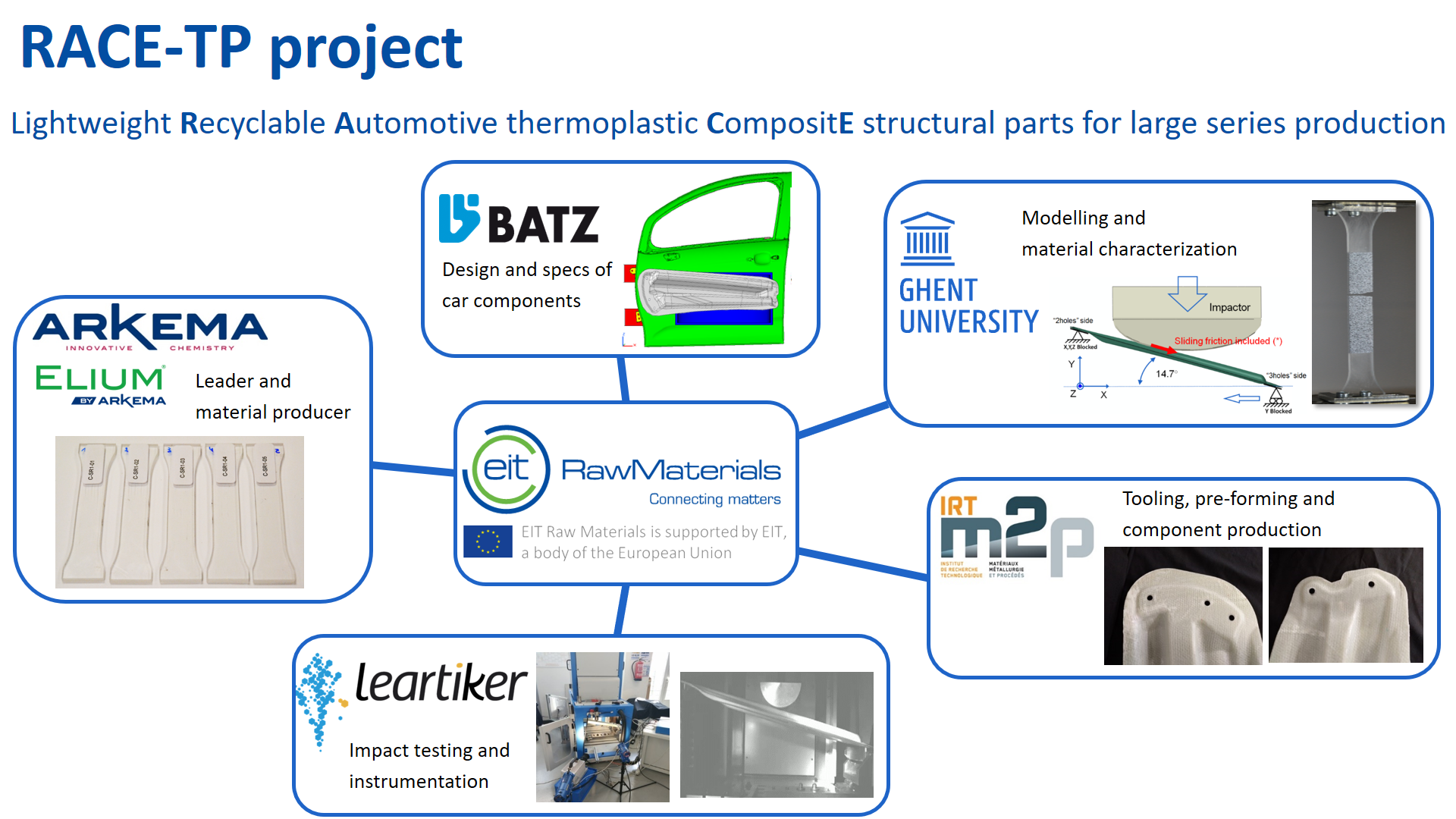

Part of our developments are promoted by collaborations from different types of research projects, while another substantial part comes from our own initiative motivated by scientific curiosity as well as in view of future applications aiming at possible new cooperations.

We carry out frequent changes to improve the previous implementation, incorporating new features and modifications at diferent levels. Because of this, the revisited models look little or nothing like the initial implementation. This is part of the scientific development.

Joint work along different projects is helping our library to gradually become richer in different directions little by little.

Below we mention some projects where some of our modules were initiated, modified, improved or extended.

Part of our developments are promoted by collaborations from different types of research projects, while another substantial part comes from our own initiative motivated by scientific curiosity as well as in view of future applications aiming at possible new cooperations.

We carry out frequent changes to improve the previous implementation, incorporating new features and modifications at diferent levels. Because of this, the revisited models look little or nothing like the initial implementation. This is part of the scientific development.

Joint work along different projects is helping our library to gradually become richer in different directions little by little.

Below we mention some projects where some of our modules were initiated, modified, improved or extended.